Antistatics

Additives

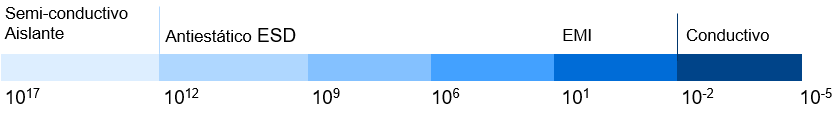

Antistatic Masterbatch Often a low resistivity is desirable to avoid the accumulation of static charges, which can be annoying in the tissues, causing the adhesion of films and preventing their manipulation, and even dangerous in the presence of flammable gases such as in the operating room of hospitals . The accumulation of static charges is avoided by adding ionizable additives that are deposited on the surface facilitating surface conductivity. They are suitable for plastic injection, plastic blowing, film blowing, plastic extrusion and polyolefin water mouth processing. Antistatic Masterbatch should be strictly chosen as an antistatic agent with fast immigration. During the production, storage and delivery procedure, antistatic masterbatch can effectively reduce static collection to a lower surface electrical resistance to ensure that there is less dust on the surface of the product. | ||