Chlorinated polyethylene

Thermoplastics > Polyolefins > Polyethylene

| CPE - chlorinated polyethylene | |

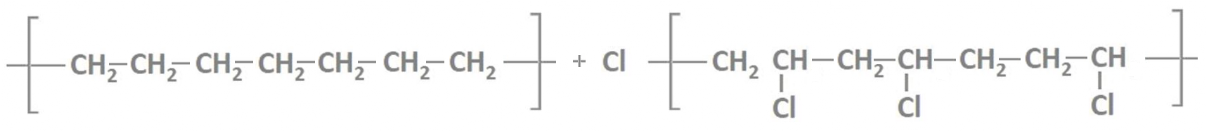

CPE is the standardized acronym for thermoplastic chlorinated polyethylene elastomer, which is produced by polyethylene chlorination. It is the polymer formed by polyethylene chains with intercalated chlorine atoms, can reach up to 45% by weight in chlorine. Chlorinated polyethylene is a type of polyethylene of the formula - (CH2-CHCl-CH2-CH2) n. Chlorinated polyethylene elastomers (CPE) and resins have excellent physical and mechanical properties, such as resistance to oils, chemicals and improved thermal properties. They can also exhibit a better compression set, flame retardancy, tensile strength and abrasion resistance. CPE polymers can vary from rigid thermoplastics to flexible elastomers, which makes them highly versatile. Hose and casing, roof, automotive and industrial, molding and extrusion, and as base polymer. These polymers are used in a variety of end-use applications. They are crosslinkable by irradiation or chemical means. CPE combines well with many types of plastics, such as polyethylene, EVA and PVC. With dimensional stability without the need for vulcanization. The excellent CPE additive / charge acceptability characteristics can provide a benefit in blends where composite performance and economy are critical. |  |

Products range | |

Mexpolimeros offers mixtures of CPE and vinyl, very robust compounds with exceptional oil, physical and flame characteristics. If environments contain oil, acids or alkalis, CPE jackets offer more protection than PVC. We have CPE based on TPO, with very low halogen content, superior properties of low temperature and good flame characteristics. We also have suitable CPE for radiation crosslinking, are oil resistant, flame retardant, electron beam curable, CPE based compounds suitable for cable and wire applications. Custom color matching is available. You can make the CPE have properties similar to plasticized PVC but can not compete with it cost. |  |

Symbols | |

|  |

| CPE Proprierties | |

Los PCEs sean amorfos o cristalinos cubren un amplio campo de propiedades.Las propiedades del polímero varían dependiendo del contenido de cloruro, peso molecular y cristalinidad. Los CPE que contienen hasta el 30% de cloro en peso son más blando, parecido a las gomas, y hay una pérdida de cristalinidad , entonces se volven más solubles en el polietileno; cuando el polímero contiene entre 40% a 45% de cloro es más duro, y con un reblandecimiento más alto. | |

Chemical properties | |

The significant advantages of the products produced from chlorinated polyethylene are its improved resistance to chemical extraction, volatility of the plasticizer and to the weather. It has good characteristics for waterproofing, it has resistance to alcohols, alkalinity, acids, oil, aging, atmospheric inclemencies, ultraviolet rays, oxidation, gases, steam and is resistant to fire. These plastics have inherent resistance to oxygen, ozone, and weather, resistance to chemical extraction and volatility of plasticizers, exceptional high tear resistance, etc. However, they show a chemical instability similar to that of polyvinyl chloride (PVC). | |

Processability | |

It can be processed by standard extrusion, calendering and injection molding. |  |

| Polimerization | |

Chlorinated linear polyethylene (CPE) is prepared by simple chemical substitution of chlorine in the linear polyethylene backbone. Chlorination can occur by directly exposing the polymer to gaseous chlorine in solution or in a finely divided form. The presence of ultraviolet light or another activator is necessary to achieve an adequate reaction rate. It can also be produced from PE that is chlorinated in a random (random) configuration in an aqueous suspension, usually in a suspension or solution of CCl4 at temperatures of 60 ° C. |  |

| CPE Applications | |

The substitution of chlorine atoms, by some hydrogen atoms, in the polyethylene chain affects its crystallinity and improves the resistance and improves the resistance to fire, oil, etc. It is widely used as PVC modifier a in combination with HDPE or LDPE sheets to improve the hardness, the sheets are used in agricultural applications. In the automotive industry is used as an elastomer for ABS systems, extruded foam-supported sheet is used for automotive, upholstery and door paneling, in the wire and cable outer jacket industry. It is also used for the coating of hydraulic cables and hoses, for joints, waterproof coatings, roofs and sheets. Flexible film is used in weather protection systems. |