SSP

Process > Polymerization

| Post-polymerization | |||

The SSP technology, in fact, allows to obtain molecular weights in the order of 27,000 (intrinsic viscosity 0.90 dl / g) typical of the quality of the PET bottle. In essence, SSP allows obtaining materials with characteristics that can not be achieved with fusion polymerization. An example of such characteristics is represented by the reduced presence in the materials obtained by the SSP of degradation products whose formation is reduced thanks to the use of lower temperatures. |  | ||

Many factors influence the SSP process | |||

|  | ||

| Reactors | |||

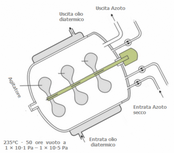

The SSP reactor is designed to guarantee the necessary residence time for the material to reach the desired intrinsic viscosity. Typical residence times vary from 10 to 60 hours, depending on the polyester used, with a temperature close to the melting point. |  | ||

| Reduce post-polymerization costs | |||

To optimize the SSP, reduce the time and, consequently, the costs, there are some measures that help reduce the post-polymerization time. More information >> |  | ||