Polyphenylene sulfide

Thermoplastics > Superpolymers

| PPS - Poli(p-fenilen sulfuro) | ||||||||

| Gama de produtos | ||||||||

In Mexpolimeros we offer a wide range of polymeric and composite elastomeric materials developed according to their needs, ensuring quality products and service. Our product range includes degrees without reinforcement, glass fiber and / or mineral filler (Ibridos), loaded with metals, modified impact, with special additives as STABILIZER heat, UV, metals, antistatic, antibacterial, laser marking , nucleated etc, and special flame retardant (with or without lubricant halogens). T lso e offer developed and evaluated by highly qualified staff and advanced technology. |  | |||||||

| Polyphenylene sulfide (PPS) | ||||||||

The polyphenylene sulfide or poly (p-phenylene sulfide) is a polymer organic compound sulfides aromatic rings. It is a thermoplastic material with high performance that combines good mechanical properties with excellent thermal and chemical resistance. In the branched version is dark brown color, while the line is clearer. Semicrystalline thermoplastic material, nonpolar, with very low absorption of H 2 O. Excellent retention of the physicochemical and mechanical properties in conditions of continuous use (210-220 ° C) with peaks up to 260 ° C. Excellent dimensional stability even in harsh environments and inherently retardantcall. It is one of the polymers has the best chemical resistance. PPS has a high strength to weight, maintaining the dimensional stability at different temperature conditions. | ||||||||

| Symbols PPS | ||||||||

|  | |||||||

| Propperties PPS | ||||||||

| ||||||||

| Mechanical Properties Physical PPS | ||||||||

Polyphenylene sulfide (PPS) is an engineering thermoplastic semicrystalline high temperature. It is a rigid and opaque polymer with a high melting point (280 ° C). Is paraphenylene units alternating with sulfur bonds. For many parts subject to high stresses PPS may be the best comparison to metal alloys, thermosetting or other thermoplastic alternative. Excellent dimensional stability (low shrinkage, CTE), very hard and rigid; high dimensional stability. PPS (Poliparafenilensolfuro) is a thermoplastic material with high performance that combines good mechanical properties with excellent thermal and chemical resistance. | ||||||||

| Thermal properties PPS | ||||||||

| The PPS does not melt until about 300 ° C. PPS provides a combination of long - term resistance to temperatures that can reach 200 ° C and short term thermal resistance up to 260 ° C. Because this material, virtually unbreakable, resists deformation by heat at 174 ° C. | ||||||||

| Electricals properties | ||||||||

Excellent electrical insulation properties, very low dielectric losses. Good electrical insulation properties and good dielectric properties. The PPS contains a very low proportion of contaminant ion which puts forward to other materials for electronic applications. | ||||||||

| Chemicals properties | ||||||||

It is ideal to use in view of the high chemical and thermal resistance chemical industry. Good chemical resistance to mineral acids, alkalis and salt solutions. Particularly suitable for metal replacement evaluation. Polyphenylsulfone (PPS) are capable of withstanding continuous exposure to moisture and high temperatures and to absorb shock without breaking. Resistance to a wide range of chemicals - including liquid fuels and automotive and aviation; strong acids and bases (pH 2 to 12), even at high temperatures. Below 200 ° C, the PPS is insoluble in all known solvents. It also resists acid s common and bases - including commercial washing solutions - over a wide temperature range. SOporta frequent sterilization by superheated steam at 134 ° C, find a wide range of applications including in the tanks for the medical sector. | ||||||||

| Processability PPS | ||||||||

All grades can be easily processed, can be processed in standard thermoplastic equipment. It can be injection molded, extruded, blow molded. In addition, clean residues of these operations can be reprocessed. Typically, the mold shrinkage of PPS products is very low. For good dimensional stability and s important that the designer of the piece understand the exceptional dimensional control that can be obtained with PPS. Moisture absorption PPS products are not hygroscopic, and therefore does not undergo dimensional expansion as polyamides. | ||||||||

| Polimerization PPS | ||||||||

Obtained by reaction with sodium sulfide to-diclorbenzene in a polar solvent such as 1-methyl-2-pyrrolidone (NMP) at 260 ° C 1.1 MPa (160 psi). PPS is a polymer in which the aromatic elements are combined together by sulfur atoms. R candles takes very special precautions in order to allow the molding process. In the original process developed, the product obtained had a low molecular weight and can be used in this form for coating applications. To produce molding grades, the PPS is cured (chain extended or crosslinked) around the melting point of the polymer in the presence of a small amount of air (SSP), this curing will proprociona one to umento molecular weight, m ost hardness, d isminución melt flow,darkening in color, p oss of solubility, d isminución crystallinity. Eventually, process modifications removed the curing step to provide products with improved mechanical strength. The regulating PPS is a linear polymeric material, whitish, of modest molecular weight and mechanical strength. When heated above its glass transition temperature (Tg ~ 84 ° C), crystallized rapidly, has a molecular weight double MW compared to regular PPS, and thanks to the increased length of molecular chain results high toughness, elongation and impact resistance PPS curing is or btenie by heating PPS in the presence regulate air (O 2 ) curing increases MW and provide some features of thermosetting type Branched PPS , t iene higher than regular PPS MW, has improved mechanical properties, toughness and ductility. | ||||||||

| Applications PPS | ||||||||

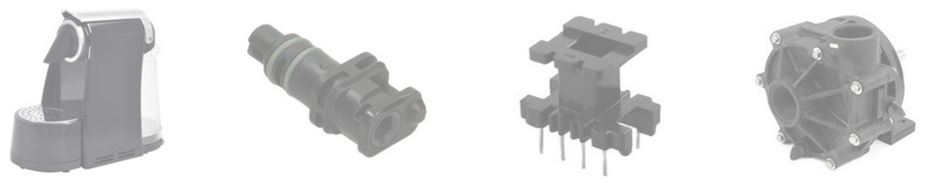

PPS is a polymer suitable for the construction of parts that must withstand high temperatures and chemical attack, parts of pumps, fans, impellers automotive industry, such as pumps, valves, system components air supply, together, components carburetion system, heating, ventilation and air conditioning (HVAC), for compressors, silencers / deposits, components of hot water circulation, blower housing induced draft, relays and switches motor ventilation components and power components thermostat. in the electricity sector good insulating power and dielectric properties make it irreplaceable in many applications as carriers for circuits, coils, insulators ,connectors, hard disk drives, electronic housings, plugs, switches and relays. Due to its outstanding dimensional stability, low density, corrosion resistance and hydrolysis, the PPS can be used to manufacture components of conditioning, handles for pans, grills hairdryers, valves steam iron, switches for toasters and dryers, microwave ovens turntables, etc. The key trend influences the growth of PPS in electrical / electronic applications is the replacement of other polymers low temperature. In medical and surgical equipment,They are used in medical applications such as surgical instruments and components and parts of devices which require high dimensional stability, strength and heat resistance. PPS fibers are also used in medical fibers and membranes. A plication in contact with drinking water (KTW) and NSF certificates are available. | ||||||||