Drying

Process

| The drying of polymers | |

Drying is a critical step in the process of using polymer polymers.Tutti, more or less, absorb moisture during production, transport. Therefore, you must remove the moisture from the resin before use, to prevent, defects in the final part, both in terms of appearance of that property. Plastic resins can be divided into two categories: non-hygroscopic hygroscopic Non-hygroscopic In this category are the resins that absorb moisture only on the surface, so it is sufficient to expose the resin to a flow of hot air (deumidificatiore) or simple heating with times however long Piau (drier). Hygroscopic resins In this category are the resins that absorb moisture within the granules, necessitani dehumidificacin granatire intense for a stable process, it is generally recommended that a moisture content of less than 500 ppm. |  |

| Types of dehumidifiers for plastics | |

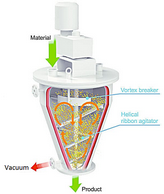

| Vacuum process | |

The vacuum process is an ideal process to remove moisture from the pellets, thanks to the absence of oxygen, oxidative phenomena are avoided. It is known that, at ambient pressure, the water vaporizes at 100 ° C but, by reducing the pressure to 800 mbar, the vaporization is around 23 ° C. The vacuum dryer can not, however, be a continuous system, but only intermittent operations are allowed. During the opening of the autoclave the material suffers heat loss and moisture absorption, altering the uniformity and efficiency. Vacuum drying is faster, more careful and more efficient from the energy point of view than heat drying. |  |

| Drying process | |

The drying process consists in injecting through the material contained in a hopper ambient air for a time and at a certain temperature. The effectiveness of the treatment depends to a large extent on the environmental conditions and is only acceptable for non-hygroscopic materials. For hygroscopic materials, in no case, will be able to obtain from a dryer the desired moisture content, because the ambient air used has a dew point (dew point) as a function of the variable environmental conditions. This implies, therefore, various drying conditions and, as a consequence, the drying is uncontrolled and not easily repeatable. The use of normal high ambient air dryers is very limited and depends in each case on the percentage of residual humidity that can be tolerated in the materials during the transformation. |  |

| Adsorption dryers | |

| Adsorption dryers are the most used (80%) for drying resins that have a tendency to absorb moisture. The deumidification is similar to the preceding process, with the fundamental distinction of the aria used being deumidificata previously. The natural attraction between hygroscopic resins and water molecules makes it take up and retain the water as soon as they are exposed to humid ambient air. Mild to moderate hygroscopic materials include ABS, acetal, acrylic, polycarbonate, PBT, LCP, and some TPO, STEP, and TPU. The most strongly hygroscopic and difficult to dry materials are quality PET for bottles and PA. | |

| De-humidification | |

| The de-humidification system consists substantially of two parts: the hopper (or hoppers), within which the actual treatment occurs; l dehumidifier (dryer), which generates dehumidified air in quantities and at the required temperature. The hopper is essentially a container of cylindrical shape, equipped with an insulation, in order to reduce the dispersion of heat to the outside. The material is poured from the upper part and extracted from the lower side during transit, the material is inverted by hot and dehumidified air. The time necessary to cross the hopper (permanence) determines the duration of the treatment. The air, which passes through the material, the resistance is the moisture that is outside the granules is the moisture that has migrated from the inside to the outside. The dew point of the air is set as it relates to air produced by the generator under certain dry conditions. The generator must provide the necessary amount of air at the temperature required by the type of pellets. | |

| Difference between dryer and dehumidifier | |

The best process undoubtedly the vacuum process is an ideal process to remove moisture from the pellets, thanks to the absence of oxygen, oxidative phenomena are avoided, the dehumidifier follows, which generates dehumidified air in quantities and at the required temperature, and finally the process of drying that consists of injecting through the material contained in a hopper air of the environment during a time and a certain temperature, but by the presence of oxygen oxidative phenomena are created. |  |