ETPV

Elastomers TPE > Segmented

| eTPV - Thermoplastic copolyester Vulcanized | ||||||||

| ETPV Products range | ||||||||

We have at your disposal the ETPV resin in a wide range of hardnesses from Shore 50A to 95A, special grades stabilized to heat, with flame retardant up to V0, for blowing, stabilized to hydrolysis and UV light as well as in the form of concentrates. black pigment. |  | |||||||

| ETPV Thermoplastic copolyester | ||||||||

ETPV consists of high-performance cross-linked rubber particles dispersed in a thermoplastic engineering polymer matrix TPC-ET. It is a halogen-free product that does not contain plasticizers and other migratory components. The thermoplastic matrix is a copolyester (TPC-ET) with the typical characteristics of a flexible plastic. | ||||||||

| Symbols | Formula | |||||||

| ||||||||

| ETPV properties | ||||||||

| ||||||||

| ETPV Physical and mechanical properties | ||||||||

The copolyester provides excellent flexural strength, low temperature properties and resistance to oil and grease, allows ETPV processing in standard thermoplastic processing equipment and is recyclable. The rubber phase is vulcanized providing the properties of the thermoset elastomers, improving the heat resistance, the chemical resistance and the hydrolysis, also the elastomeric phase lowers the hardness, improves the compression set, and the elongation of the copolyester. The combination of these components, rubber and copolyester allow other advantages, such as design flexibility and fast cycle times, which leads to improvements in overall performance and cost savings of the system compared to vulcanized rubber. | ||||||||

| ETPV Thermal properties | ||||||||

ETPV retains the mechanical properties in a wide range of temperatures from -40 ° C to 160 ° C up to 180 ° C (with heat stabilizers). Provides fine thermal resistance at 3000 hours at 150 ° C. They have a point of 190 ÷ 220 ° C of fusion, depending on the hardness, high performance at extremely low temperatures, the ETPV maintains the physical-mechanical properties (resistance to impact) up to -40 ° C with peaks of up to -60 ° C . | ||||||||

| ETPV Electrical properties | ||||||||

ETPV combines excellent insulating properties and is clearly superior to other polymers, allowing to achieve in particular the kind of insulation with thinner walls than other conventional polymers. Minor consequence cost per meter, which reduces cables and duct dimensions and weight reduction can be achieved by using as ETPV insulation | ||||||||

| ETPV Chemical properties | ||||||||

ETPV are high performance elastomeric thermoplastic with excellent chemical resistance and compatibility to different fluids used in the industry. Excellent resistance to petroleum products and mineral oils, good contact with alcohols, ketones, aromatic hydrocarbons and decent with a non-aggressive acid. | ||||||||

| ETPV Procesabilidad | ||||||||

They can be processed by injection molding, 2K molding, blow molding and extrusion. ETPV resins are well processed in commonly available injection molding machines without special requirements. The melt is non-corrosive, the hardened or standard nitrided barrels and screws are suitable. The recommended melting temperature range for ETPV in injection molding is 240-265 ° C. | ||||||||

| eTPV Compound | ||||||||

Polymer blends are generally prepared by melt mixing. ETPV are normally produced by blending techniques of an elastomer, copolyester and vulcanizer. In general, the mixing extruders and twin-screw extruders of joint mixing of joint rotation with a high L / D ratio are suitable for the preparation of ETPV in a continuous process. | ||||||||

| eTPV Applications | ||||||||

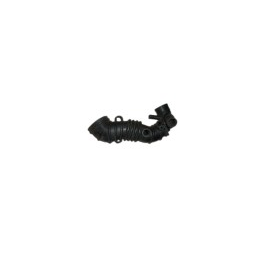

They are very desirable for many different applications. They can be processed by injection molding, 2K molding, blow molding and extrusion. In the automotive industry, ETPV can serve a wide variety of applications, from extruded hoses under the bonnet to injection molded plugs, ignition coil seals and oil seals. ETPV can also be blow molded for parts such as air ducts, bellows and CVJ boots, air ducts with an approximate length of 1 meter . |  | |||||||