PA 46

Thermoplastics > Polyamides

| Polyamide 4.6 - PA 4.6 Polytetramethylene adipamy | ||||||||

PA 4.6 similar to PA 66 or PA 6, but has a greater number of amide groups for the same chain length and a more symmetric structure of the same chain. This leads to obtain a product with a higher melting temperature of 295 ° C, and a higher crystallinity (70/80%), which allows a faster crystallization, thanks to the presence of very small spherulites, then faster molding cycles . Polyamide 4.6 (PA4.6) is suitable for continuous use up to 150 ° C, bringing it closer to superpolymers, such as PPS and PEEK. With its favorable price / performance ratio, this polymer is an excellent choice for high temperature applications. The moisture absorption of PA4.6 is quite high, 4.5% at 23 ° C / 50% RH and 13% after saturation in water at 23 ° C, in fact the stiffness is significantly altered in terms of fatigue resistance , the grades reinforced with fiberglass are close to PEEK, while the resistance to cold deformation is very excellent. | ||||||||

Symbols | ||||||||

| ||||||||

| Properties PA 4.6 | ||||||||

|  | |||||||

| Thermal properties PA 4.6 | ||||||||

PA 4.6 is the polyamide that reaches the highest utilization temperature, even higher than the acetal and polyester resins, which resists up to 150ºC. In the temperature range of 80-150 ° C, PA 4.6 presents, therefore, better mechanical qualities, resistance to creep, wear, aging and fatigue compared to others of equivalent grade. PA 4.6 is a highly hygroscopic material. | ||||||||

| Chemical properties PA 4.6 | ||||||||

They are well resistant to aliphatic and aromatic hydrocarbons, gasoline, oils, fats, some alcohols, esters, ketones, ethers, many chlorinated hydrocarbons, weak alkaline solutions Effective resistance to aging Good resistance to weathering. They do not resist well to mineral acids, strong alkaline solutions, solutions of oxidizing agents, formic acid, phenols, cresols, glycols, chloroform, dichloro difluoromethane (freon), caustic potash at 50% concentration, aqueous carbamide, ozone, difluoro aqueous methane of carbamide (Freon). |  | |||||||

| Electrical Properties PA 4.6 | ||||||||

| Depending on the percentage of water absorbed, the electrical resistance decreases considerably due to the high absorption of moisture, which is why it is not suitable for high voltages. Good surface resistance and, therefore, good resistance to slip currents, low and stable high frequency dielectric value excellent arc resistance |  | |||||||

| Processability PA 4.6 | ||||||||

Polyamides 4/6 can be easily molded by injection or blow molding, extrusion or using the rotation system. The film, the sheets, the bars, the rings and the pipes (plasticized or others) can also be produced by extrusion. Polyamides 4.6 in the form of powder are also used as protective coatings, such as heat-sensitive powders or in solutions such as glues, waterproofing, etc. Semi-finished parts, sheets, bars and rings are very easy to process mechanically. |  | |||||||

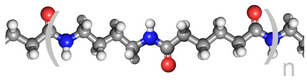

| Polimerization PA 4.6 | ||||||||

PA 4.6 is an aliphatic polyamide that is formed in polycondensation by reaction between 1,4-diaminobutane and adipic acid. However, similarly to PA 66 or PA 6, PA 4.6 has a greater number of amide groups for the same chain length and a more symmetric structure of the same chain.  |  | |||||||

| Products range PA 4/6 | ||||||||

PA 4.6 is offered in a wide variety of grade including no filler / no reinforcement, as well as grade that contains fiberglass, mineral filler, hybrid 2 or more full, with special additives and special lubricant, modified impact and retardant of flame. |  | |||||||

| Applications PA46 | ||||||||

Electrical connectors, sockets, pin terminals, external electrical components, gear engineering components, air ducts, manifolds, alternator components, chain tensioners, oil filter bodies, actuators. |  | |||||||