Injection molding

Process > Injection

| Molding Injection | ||

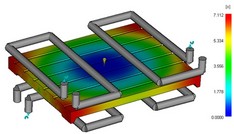

Injection molding is by far the most used processing technique to produce parts from thermoplastic elastomers due to its high productivity. Injection molding machines and molds are very expensive due to the high pressures required and the complexity of process control. However, the drawback of this technique is compensated for by its ability to produce a complex finished part in a single and fast operation. The principle of injection molding is very simple, is to feed the pellets or grains to a heated barrel where it melts, then being cast is forced to pass through a chamber with matrix or bipartite die, using a hydraulic plunger or with the screw Rotary of an extruder. As the pressure increases at the entrance of the mold, the rotary screw begins to move backward, under pressure, to a predetermined distance; this movement controls the volume of the material to be injected. The screw then stops rotating and is pushed hydraulically forward, forcing the molten plastic into the mold cavity. The piece of plastic is created by cooling the material inside this mold. The mold is constantly cooled to a temperature that allows the melt to solidify and the mold opens, the finished product is expelled and the process continues. The injection of plastics is a process that allows us to manufacture plastic parts and objects of high precision, with clean and smooth surfaces. In addition, the material used is used in its entirety. |  | |

Factores adicionales que afectan la adhesión | ||

Production levels are very high, even with complicated shapes. The costs are lower, especially if the injection process is outsourced. The manufactured parts require few finishes. The handling of material is reduced. The initial cost in molds is high High production levels and low costs Molding of parts with very complicated geometries High or low automation, this depends on the value of the piece. Once finished pieces require little finishing, they are finished with the desired roughness, color and transparency. Material handling is reduced because of the press hopper will usually contain enough material to mold pieces for an extended period. The larger and smaller diameter core pins can be used because they can be held at both ends. After the mold has been closed before any material is injected into it, parts containing metal inserts can be molded without burrs of material in the inserts. The relatively tighter tolerances through the separation lines are possible. The flash in the separation line can be maintained at a minimum thickness if the mold is properly designed and well maintained. The injection molding of thermoset materials is apt to automate the process which can result in low prices per piece. Deformation can be a problem in injection molding because the injection materials have smoother flows and more shrinkage. Forcing the material through the sprue, channel and inlet can guide the material producing non-uniform shrinkage. Filling the pieces with one of the two entrances produces pieces that have dotted lines. These dot lines are the weakest areas in the piece. The amount of scrap in total produced during injection molding will usually be higher than that of compression molding because of the additional scrap created by the sprue and channel. In the past, heat-hardened scrap had to be disposed of in a garbage dump. However, some thermosetting materials are now being successfully recycled. | ||