Natural rubbers

Rubbers > Group R

Natural Rubber (NR) | ||||||||

Natural rubbers, or natural rubber, also called rubber, are obtained by coagulation of the latex obtained from some tropical plants (in particular Hevea brasiliensis) and were collected by incision from the trunk of the plant. It requires vulcanization, a process by which crosslinks are created between the rubber polymer chains by heating in the presence of sulfur. The crosslinks increase the rubber resistance and act in a certain sense as a "memory" that helps the polymer to recover its original shape after a stretch. The plasticity of the rubber varies from tree to tree and also depends on the amount of finger work to the rubber from the latex state, from the bacteria that accompany it and influence its oxidation and other factors. The natural rubber shows, unlike other synthetic rubbers, the special characteristic of the reversible crystallization when stretching and releasing. | ||||||||

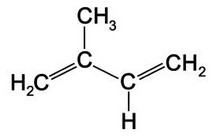

Symbol | Structure | |||||||

|  | |||||||

| NR Properties | ||||||||

| ||||||||

| NR Physical-Mechanical properties | ||||||||

Like many elastomers, the physical properties of rubber change with temperature. Heating up to 100 ºC., Softens and undergoes permanent alterations. At low temperatures, it becomes rigid, and when it is below the Tg it acquires a fibrous structure. Due to its plastic nature, natural rubber acquires great permanent deformation. It provides excellent physical, mechanical properties, and excellent elastic performance, but it does not withstand atmospheric agents, temperature and many chemical compounds. Elevated gas permeability, therefore, is not suitable for the purpose, good elettrico insulation. Resistance of ozone, aging and weather, rather limited. However, it can be improved with the addition of antiaging and antiozonants as a protective wax. | ||||||||

| Caucho procesabilidad | ||||||||

La procesabilidad es mejor cuando el peso molecular del plástico es bajo, mientras que las propiedades del producto acabado son mejores cuando su peso molecular es alto. En la práctica la mayor cantidad de plásticos utilizados se eligen con un peso molecular intermedio entre su procesabilidad y las propiedades finales del producto, pero dada la gran variedad de plásticos y procesos, particularmente en los termoendurecibles, cauchos y recubrimientos, se debe elegir el plástico y el proceso que permitan al mismo tiempo obtener, la mejor procesabilidad y las mejores propiedades en el producto acabado. En la fabricación moderna de artículos de caucho natural, el caucho crudo se trata con varios compuestos mezclándolos en máquinas. La mezcla se aplica entonces mecánicamente a una base o molde, y el objeto revestido o formado de la mezcla se pone en moldes y vulcaniza. | ||||||||

| NR applications | ||||||||

Technical articles of any kind: pipes, gaskets, membranes, rubber and rubber / metal spring elements, for suspension motors, door and window profiles, hoses, belts, mats, floor coverings and shock absorbers for the automotive industry automotive Tires for motor vehicles, conveyor belts, cinghie. Commonly used items, such as rubber boots, shoe soles and heels, gloves, pacifiers, sponges, rubber threads, adhesives, gloves, balloons and erasers. | ||||||||