| TPC-ET High Performance Copolyester Elastomer | XFLEX TPEE

|

|

|

| Thermoplastic Copolyester Elastomer (TPC-ET)

|

|

|

|

We have available the TPC-ET resin in a wide range of hardnesses from shored 25 to 72D, special grades stabilized heat with flame retardant to V0, for blowing stabilized to hydrolysis and UV and shaped black pigment concentrates.

|

|

|

| TPC-ET thermoplastic polyester elastomer

|

|

|

|

The TPC-ET are products combine the advantages of vulcanized rubber products with ease of processing of thermoplastics. It is based on a thermoplastic elastomer ether ester (TPC-ET) with hard segments of polyester, polybutylene terephthalate and polyether soft segments. No need to add any plasticizer. Thus, a modification of properties due to migration of plasticizers is avoided. Proporcionea better mechanical performance, especially under conditions of maximum stress, an excellent shape recovery, good balance between stiffness and low temperature properties, resulting in lower thermal stability and excellent molding variations processing capabilities. Thermoplastic polyester elastomers can be used at higher temperatures than the TPE.

|

|

|

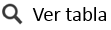

| Name - Symbol

| Formula |

|

|

|

- TPC-ET

- COPES

- TEEE

- TPEE

- TPE-E

- PESTEST

- Thermoplastic Copolyester Elastomer

- Thermoplastic copolyester

- Thermoplastic polyester elastomer

| |

| Thermoplastic Polyester Elastomer (TPC-ET) Properties

|

|

|

|

- Excellent resistance to flexural fatigue

- Inrush high temperature

- High impact resistance

- High abrasion resistance and tear

- Good resistance to chemicals and weathering

- High load capacity

- Overmolding excellent adhesion (ABS / PBT / PC / metals)

- Excellent resistance in a wide temperature range

- Excellent dynamic properties, p. g., creep and fatigue

- Exceptional chemical resistance, oil and grease

- Processed with a high degree of versatility

- Good electrical insulation properties

- Low moisture absorption

- Excellent dimensional stability

| |

|

| TPC-ET Mechanical and physical properties

|

|

|

| It provides balance between flexibility and strength in various applications: heat insulation, seals and hoses. Resists tearing, cracking under flexing, abrasion, and fatigue. It provides strength and rigidity coupled with extraordinary toughness and good retention of properties at temperatures elevadas.Las harder versions exhibit superior chemical and thermal resistance while softer grades have good mechanical properties at low temperatures.

|

|

|

| TPC-ET Thermal properties

|

|

|

|

TPC-ET retains the mechanical properties over a wide temperature range from -40 ° C to 120 ° C to 150 ° C (heat stabilizers) .They point of 160 ÷ 220 ° C melting, depending on the hardness, high performance at extremely low temperatures, the TPEE not stiffen in the cold season, maintaining the mechanical properties (impact resistance) to -40 with peaks up to - 60 ° C.

|

|

|

| TPC-ET Electrical properties

|

|

|

| TPC-ET combines excellent insulating properties and are clearly superior to other polymers, allowing to reach particular insulation class with thinner walls than conventional polymers. Lower cost per meter consequence, reducing cables and duct dimensions and weight reduction can be achieved by using as insulation TPC-ET

|

|

|

| TPC-ET Chemical properties

|

|

|

| TPC-ET is an high performance elastomeric excellent chemical resistance and compatibility to different fluids used in the industry made.Perfect resistance petroleum products and mineral oils, good contact with alcohols, ketones, aromatic hydrocarbons and decent a thermoplastic acid not agresivo.No resist contact with strong acids, even in low concentracione

|

|

|

| TPC-ET Processability |

|

|

| There are degrees of TPC-ET thermoplastic for each processing method. The TPC-ET supports different equipment procesamiento.Los TPC-ET are supplied as granules or pellets are converted into end-use items using conventional thermoplastic processing techniques such as injection molding, extrusion, blow molding , thermoforming and calendering.

| |

|

| TPC-ET Polimerization

|

|

|

| It occurs in two steps: in a first reactor is carried out transesterification (is the transformation of an ester into another ester by reaction with an alcohol) between DMT (dimethyl terephthalate) and 1,4-butanediol (in excess), transferred to a second reactor in the second stage it is carried out polycondensation by adding a polyol such as PTMG, in the presence of catalyst (tetrabutyl titanate).

|

|

|

| TPC-ET Applications |

|

|

| It is ideal for applications and parts that require excellent flexural strength in a wide temperature range of use. It is not intended to aplicacioes setor of automóveis of consumer and industrial bens em geral.Gracias their excellent properties can be employed in electrical mechanical sectors ,, electronic cars and sporting goods, CVJ, boots, air duct, water seals, seals, gaskets, boots, belts, hoses ,, wires T4 hydraulic class spiral cables, wires, railpad, diaphragms, valves, caps, closures.

|

|

|

|

|

|

|

|