TPO

Thermoplastics > Polyolefins

TPO thermoplastics polyolefins | ||||||||

These are mechanical mixtures (without crosslinking), EPDM rubber and polyolefin plastic, such as PP and / or PE. Additives are usually added to modify properties such as flexibility, moldability and extrusion. These compounds have excellent tenacity, moderate elasticity and good weather resistance. The TPO range can be easily self-colored with the use of suitable masterbatch or provided as pre-colored compounds. Its advantages are its very low densities (around 0.88), constant quality, most popular grades, medium to low price. Its disadvantages are poor recovery properties at moderate and especially high temperatures. | ||||||||

Symbols | ||||||||

|  | |||||||

| Proprierties TPO | ||||||||

| ||||||||

| Products range TPO | ||||||||

| We have at your disposal the TPO resin in a wide range of hardness from ShoreA 30 to 50D, special grades stabilized to heat, with flame retardant, for blow, stabilized to hydrolysis and UV light as well as in the form of black pigment concentrates . | ||||||||

Physica and mechanical properties TPO | ||||||||

TPO has excellent strength to shorten growth while being flexible, high density and excellent fatigue resistance, and good resistance to many acids and base and aqueous solutions. The flexibility of TPO varies from elastic, 35 on the Shore A scale, to hard, 50 on the D scale. General purpose grades are appropriate for many utilities, and also available on PDAs, on the NSF list and medical degrees. | ||||||||

Thermal properties TPO | ||||||||

The pieces made of TPO offer a constant temperature range of service from -60 to 110ºC without cracking or stickiness. Excellent heat aging combines with resistance to oils and greases for exceptional durability. The degrees of fire resistance meet the requirements of the Underwriters Laboratories. These grades are UL 94 V-0 or UL 94 HB. | ||||||||

Chemical properties TPO | ||||||||

| TPO has excellent strength to shorten growth while being flexible, high density and excellent fatigue resistance, and good resistance to many acids and base and aqueous solutions. | ||||||||

| Electrical Properties TPO | ||||||||

They are good electrical insulators, with constant electrical properties over a wide range of temperatures and frequencies. They are generally used in overmolding rigid elements in electrical systems. | ||||||||

| Processability TPO | ||||||||

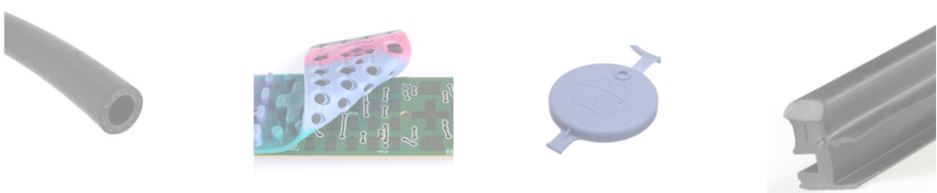

TPO can be processed in standard thermoplastic equipment. It can be injection molded, extruded, blow molded and thermoformed with the efficiency and economy associated with thermoplastic materials. Additionally, clean waste from these operations can be reprocessed. | ||||||||

| Compound TPO | ||||||||

EPDM compound with polypropylene | ||||||||

| Applications TPO | ||||||||

Typical applications are in automotive, seals, construction, appliances, console box, steering wheel, non-slip inserts, knobs, buttons, seals, profiles, pedal covers, air bags cover, locks, soft-touch armrests, sleeve, bellows, supports, spacers, wheels, fenders, racks, spoilers, wings, flaps, spoilers, air ducts, air deflectors, accessories boards, pipe fittings, DDE, wheels, adjustable, seals for vacuum cleaners, tools electrical, cable joints, connectors and boxes, cable linings, switches, boxes, garden tools, knobs, shock absorbers, "O" Rings. | ||||||||